Here's What No One Tells You About Cooling Tower

Table Of Contents

1.What Are Tooling Towers Used For?

3.What Are The Cooling Tower Working Principle?

4.How Many Types Of Tooling Towers Are There?

5.How To Install Cooling Tower?

6.How Does a Cooling Tower Work?

7.How Do You Calculate Cooling Tower Efficiency?

8.What Are Cooling Tower Parts?

10.Why Do You Need a Cooling Tower?

Section 1

What Is a Cooling Tower?

People also ask: "what is a cooling tower?" ,so I tell you cooling tower definition.

The cooling tower, especially hvac cooling tower, is a system based on recycling of water, Which reduces the water consumption, saving energy resulting in low operation & production costs. It mainly uses the technology of air and heat exchange.

1) The heated industrial water is sprayed to the cooling tower fills, and contacts with the air which inlets from the bottom of the tower for heat transferring

2) Then the heat is exhausted out of the tower by the fan, and the water cooled down is collected back to the water tank for circulating.

Section 2

What Are The Cooling Towers Used For?

Simply say, cooling towers are created for unwanted heat.

Cooling towers are used to dispose of ("reject") extra heat from the chiller.

The cooling towers, especially HVAC cooling tower, are used in many fields and industries. They are mainly used in air conditioning cooling system, injection, foaming, power generation, steam turbine, air compressor, industrial water cooling and other fields. The effect for cooling tower is to exchange the industrial water of waste heat with the air in the tower, so that the waste heat can be transmitted to the air and the cooling water can be reused. It mainly used in schools, large office buildings, hospitals, industrial plants, and etc.

Section 3

What Are The Cooling Tower Working Principle?

Now that you've figured out how cooling tower work, it's time to know cooling tower working principle

The cooling tower is actually a device for cooling water, which include many parts such as the distribution system, fill material and etc. It mainly works based on the principle of evaporate cooling. To cut down the cost and protect the environment, the industrial water are usually recycled through the cooling tower treatment.

The cooling tower uses natural ventilation or mechanical ventilation to cool the sprayed water. The whole process is as below:

1) The hot industrial water is pumped up to the top of the cooling tower.

2) Through the distribution system, include the drift eliminators and cooling tower nozzles, the hot water are sprayed out to the filling pack.

3) At the same time, the air is drawn through the air inlet louvers to forcing water to evaporate.

4) After the heat and air exchange, which means the evaporation process, the heat is able to be removed. And the cooling effect is realized.

Section 4

How Many Types Of Cooling Towers Are There?

You've know a cooling tower working principle you want, and you should know types of cooling towers now.

Cooling towers might be one of the most important parts for the industrial process. There are mainly two types of cooling towers according to the different technologies to cool the heat industrial water. You can better understand the different cooling tower types through the quick guide as below:

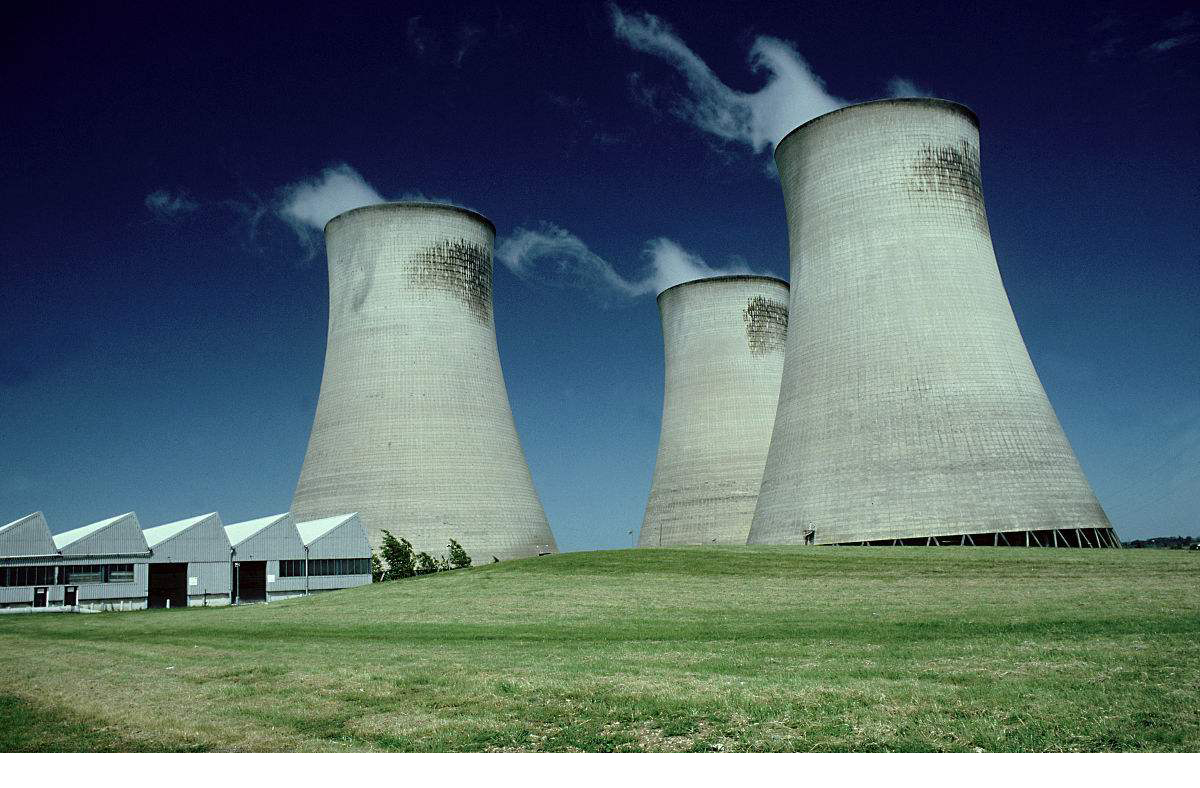

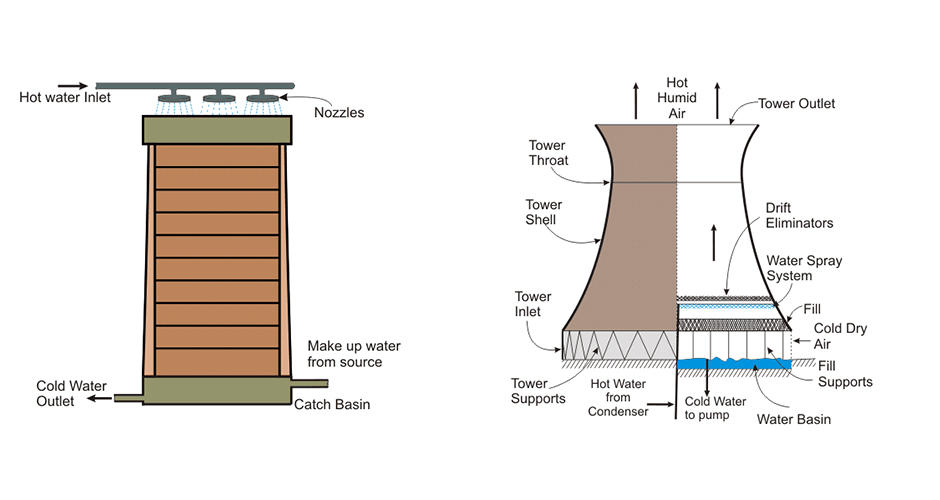

1) Natural draft cooling towers.

You can see it from the name that this type of cooling tower is rely on the natural ventilation of air throughout the tower to cooling water. Air movement occurs due to differences in density between the entering air and the internal air within the tower. Warm and moist air inside is more denser than the cool air outside. So the moist warm air will naturally rise through the tower, while the dry, cool air from outside will fall, thus creating a constant cycle of air flow.

2) Mechanical draft cooling towers.

2) Mechanical draft cooling towers.

Unlike natural draft cooling towers, mechanical draft cooling towers mainly use fans or other mechanics to circulate air through the tower. Mechanical draft towers are more effective than the natural draft cooling towers. But they consume more power and cost more than the natural type towers.

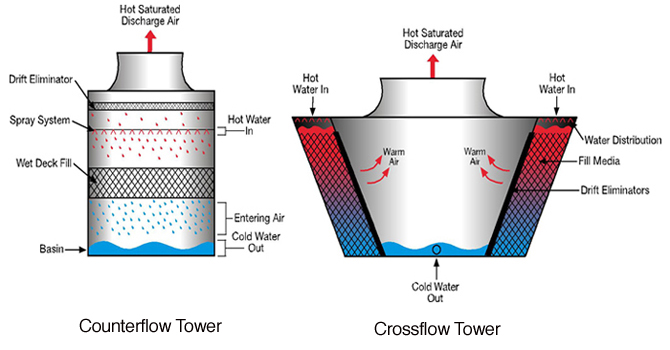

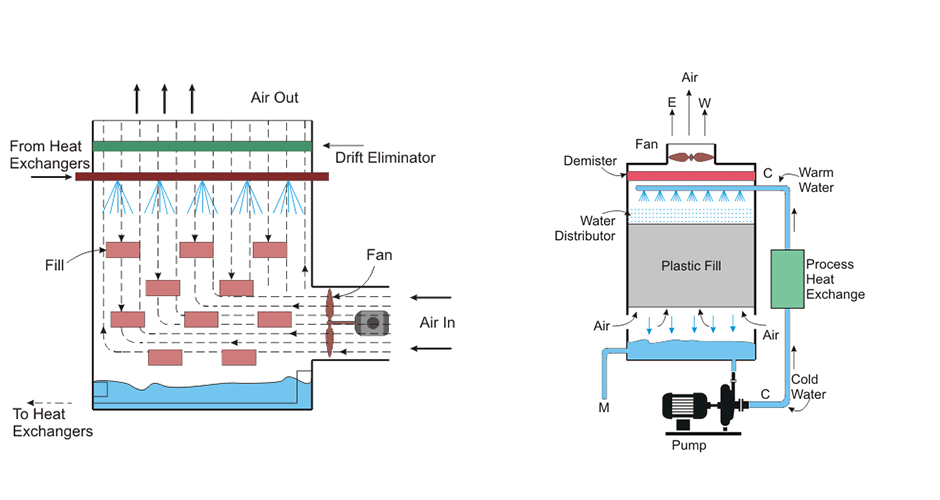

Among the mechanical draft cooling towers, the most common used type is cross flow cooling towers and counter flow cooling towers. Usually, the cross flow cooling tower is with square type, and the counter flow cooling tower is round type, such as FRP cooling tower

♦ Cross flow cooling towers diagram

In a cross flow tower, air flows horizontally through the cooling tower's structure while hot water flows downward from distribution basins. Cross flow towers can be as tall as counter flow towers, but they're also more prone to freezing and are less efficient.

♦ Counter flow cooling towers diagram

Counter flow towers move air upward through the tower while water flows downward to cool the air. These towers are often more compact in footprint than cross flow towers, and can save energy in the long run.

In all, counterflow vs crossflow cooling tower efficiency , I think the counter flow cooling tower is more efficient than the cross flow type.

Section 5

How To Install Cooling Tower?

cooling tower installation guide (Step-By-Step Case Study)

There are many requirements and conditions need to be considered, when you try to install the cooling tower. Firstly, you have to install the cooling tower in a well ventilated place so that the cooling effect can be maximized.

Secondly, the tower should be located exactly as the construction drawing showed, and placed horizontally and stably.

Thirdly, make sure the outlet of the cooling tower and the direction and position of the nozzles should be correctly installed.

You may check the details for the cooling tower installation as below:

STEP 1: Installation of cooling tower components.

♦ To install the film type water dripping device, which include the different types such as membrane plate type, paper honeycomb type, point wave type and oblique type etc.

♦ Membrane plate type sprinkling device is usually made of wood, asbestos cement board or plastic plate.

♦ The paper honeycomb sprinkling device can be directly mounted on angle steel or flat steel bracket, and can also be directly mounted on small concrete supports.

STEP 2: Installation of water distribution device. There are two kinds of water distribution devices: fixed pipe type water distributor and rotary pipe type water distributor.

♦ The nozzle of the fixed pipe type water distributor is arranged downwards according to the plum blossom shape or the square shape, and the concrete arrangement is shaped. This type shall be in accordance with the technical conditions of the equipment or the requirements of the design. The distance between the general nozzles is set according to the water spray angle and installation.

♦ Membrane plate type sprinkling device is usually made of wood, asbestos cement board or plastic plate.

♦ The installation of the nozzle of the rotary tubular distributor consists of the following three kinds:

1) a water distribution pipe with a slit is installed and the width of the slit is generally 2 to 3nvn, and the horizontal seam is arranged.

2) Nozzle water distribution, installed according to the technical conditions or design requirements of the equipment.

3) a water distribution pipe with a round hole is installed, with an aperture of 3 to 6mm and a hole spacing of 8 to 16mm.

STEP3: Installation of ventilation equipment for cooling tower. According to the different types of cooling towers, there are two ventilation systems: induced draft type and blowing type.

♦ When choosing the induced draft type, the motor cover and rotor should have good waterproof measures. A closed squirrel cage motor is used, and the terminals are sealed with rosin or other sealed insulating materials.

♦ When choosing the blowing type, the distance between the fan and tower should be more than 2 meters in case that the fan be splashed with water droplets.

STEP4:Installation of cooling tower drift eliminator. The drift eliminator also called water collector is usually installed above the water distribution pipe. It is used to block the water droplets out of the air outside the cooling tower.

Section 6

How Does a Cooling Tower Work?

Learn the basics of cooling tower work is essential to make your cooling tower system run efficiently.

A cooling tower works to lower the temperature of the cooling tower through the heat exchange by contact between air and water.

During the process of heat exchange, some water are evaporated and circulated throughout the tower so as to lower the temperature. The whole cooling down process is summarized as below:

1) Firstly, The industrial heated water is pumped through pipes directly into the cooing tower. And the cooling tower nozzles and drift eliminators are then used to spray the water and complete the water distribution process.

2) Secondly, the sprayed water flow into the cooling tower fills. And during the flow process, the fills media works to slow down the water flow and realize the maximum contact between the air and water. The air is being pulled by a motor-driven electric cooling tower fan below the tower. At the same time the air inlet louver is put into use.

3) Thirdly, when the air and water come together, the evaporation of some water generated and thus the cooling effect realized.

4) Finally, the colder water is pumped back to the industrial equipment and reused. It repeats the loop over and over again to constantly cool down the heated industrial water to complete the recycle process.

Section 7

How Do You Calculate Cooling Tower Efficiency?

It is important to calculate cooling tower efficiency. We can know how much is cooling tower consume every year

Cooling tower efficiency can be expressed as below:

μ = (ti - to) 100 / (ti - twb) (1) where:

μ = cooling tower efficiency (%) - the common range is between 70 - 75%

ti = inlet temperature of water to the tower (oC, oF)

to = outlet temperature of water from the tower (oC, oF)

twb = wet bulb temperature of air (oC, oF)

The temperature difference between inlet and outlet water (ti - to) is normally in the range 10 - 15 oF

Section 8

What Are Cooling Tower Parts?

Common cooling tower parts list you know.

Cooling tower parts also known as the cooling tower components are widely used for the cooling tower users. Our company has been offered various cooling tower parts for more than ten years. A cooling tower needs many different parts, gears and components in order to perform well, and the main parts are as below:

• Cooling tower fill packing usually with PVC or PP material.

• Fan belts and fan pulleys, bushings and sheaves.

• Gear Reducers.

• Water distribution system which includes spray nozzles, spray headers and other such items.

• Gear oil and bearing lubrication grease.

• Air Inlet Louvers, drift eliminators and many other such different types of parts and components.

Section 9

Cooling Tower Applications

You should konw common applications.

Cooling towers are widely used in many fields. such as:

• Air conditioning equipment

• Cold storage

• Cold rooms

• Refrigeration

• Heating and air conditioning

• Food industry

• Pharmaceutical industry

• Metal casting

• Plastics industry

• Rubber industry

• Textile industry

• Steel mill

• Chemical industry

• Petrochemical products

• Hydraulic presses

• Air compressors

• Generators

• Steam turbines

• Engines

• Chillers

• Diesel Generator Sets

• Process Cooling

• Pharmaceutical Industries

• Oxygen Plants

• Welding Machines

• Dry Cleaning Machines

• Other industries

Section 10

Why Do You Need a Cooling Tower?

Today you can save resource

We all know that the cooling tower is used to cool down water during the process of industrial production. After the cooling down process, the water can be recycled and thus save water resource and energy.

You might also like

Categories

Trending