Drift Eliminators

Various Typles of Drift Eliminators

Cooling Tower Drift Eliminator Types

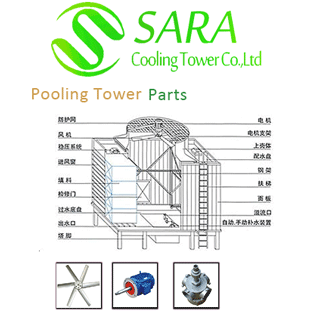

What Is Drift Eliminator

Drift Eliminator is one of cooling tower parts. By using drift eliminators, water is effectively recycled. This does not only save water, but also prevents the escape of chemically contaminated water into the environment.

The most notable drift eliminator’s description is perhaps the one that indicates its aid in the reduction of water loss and emissions. Its main goal is to minimize the drift rate and pressure drop as much as possible.

The Benefits of Using Drift Eliminators

Installing drift eliminators in cooling towers, especially in large-scale production businesses has significant advantages not just for the owners but for nature as well:

-

Keeps nearby roads and fields from icing.

-

Prevents the corrosion of piping systems and electrical parts.

-

Helps to prevent short circuits resulting from damaged electrical systems.

-

Significantly reduces harmful emissions of chemicals into the environment.

-

Largely contributes to water conservation.

-

Reduction of pressure drop in water.

-

Eliminates the need for additional water treatment.

-

Extends the life of a cooling tower.

-

Conserves energy use.

Cooling Tower Drift Eliminators Key Structures

A drift eliminator is a simple but significant part of a cooling tower. With its simplicity, it is only composed of few basic structures that make it a useful accessory that is also quite easy to install and use.

Seal

Seal prevent drift bypass, seals are usually added during the installation process. This ensures that no droplets of water can escape during the redirection process.

Filter

Filters help to remove contaminants such as chemicals that can be released into the environment.

Walls or blades

While the designs for walls or blades may vary, they all function as the main structure that propels the direction of water into the desired direction. Depending on the design, this part forces water droplets back into the cooling tower to be used again.

Seal - to prevent drift bypass, seals are usually added during the installation process. This ensures that no droplets of water can escape during the redirection process.

Types of Drift Eliminators

There are a handful of available drift eliminator designs today. However, these models are generally classified only into two main types of drift eliminators:

Counterflow Drift Eliminators - this type employs a mechanism where the air flows through the fillings in a vertical path at the top. On the other hand, the water flows from top to bottom, which makes it possible to exhaust more air faster than the process of pulling it in.

Advantages of Use

-

Lower energy consumption.

-

Maintenance is minimal.

-

Lower pumphead.

-

Plume Abated Systems.

Crossflow Drift Eliminators - on the contrary, this eliminator type has a horizontal air flow while water flows in the same downward manner. This type of eliminator also uses a splash type of fill.

Advantages of Use

-

Minimal noise.

-

Cost-effective.

-

Low maintenance required.

-

High performance.

-

Consumed energy is optimized

Different Drift Eliminator Designs

The following design types may come in either crossflow or counterflow mechanism. Essentially, this means they are installed horizontally (counterflow) or vertically (crossflow).

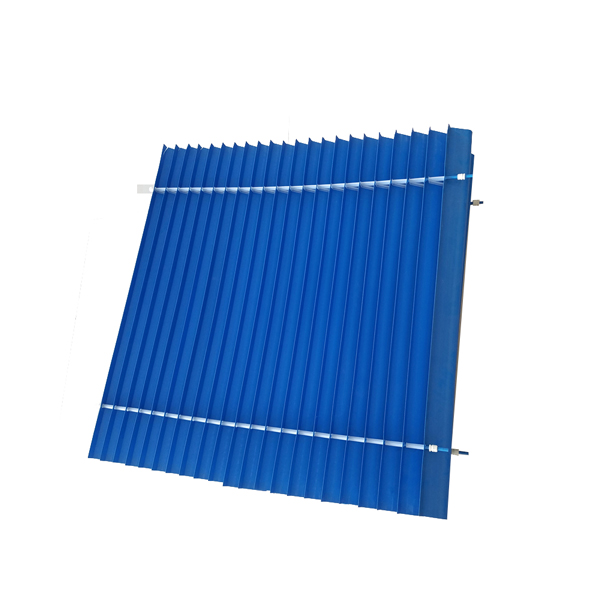

Blade - made of gauge blades which are bound by caps at both ends. Blade designs are intended to be light in weight but strong in durability.

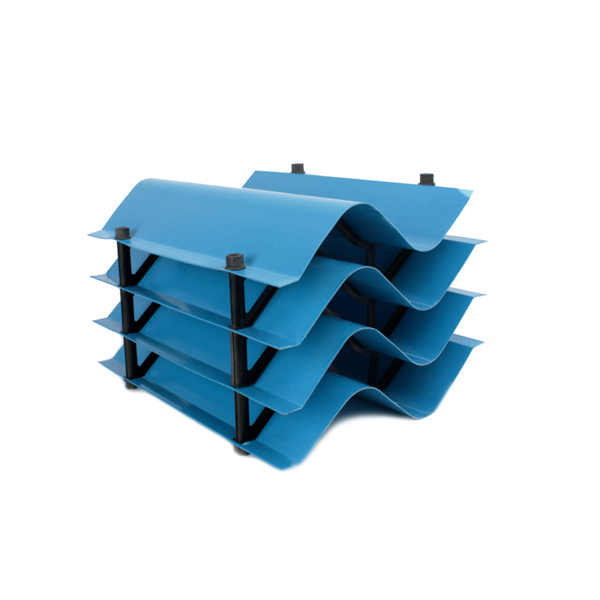

Cellular - these closed cells look like structured waves, which can force droplets of drift into three different directions. By doing this, a centrifugal force is created to keep the drift away from the stream of air.

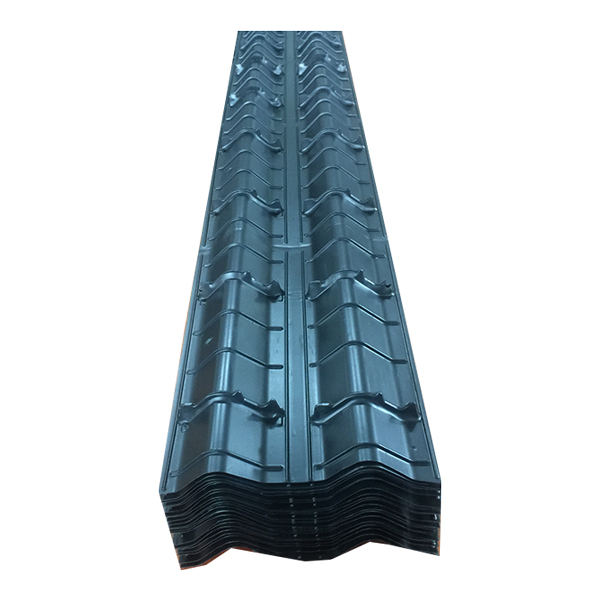

Cassette - this lightweight but robust design makes lifting and removal easier. It is also ideally used in retrofitting and has a longer lifespan.

Fill-integrated - this type uses fillings such as carbon black, which is integrated inside the main material to enhance it lifespan. The use of fillings also helps to protect the primary material from corrosion.

Common Materials Used in Drift Eliminators

There are only a few drift eliminator materials used by manufacturers today. However, this makes options easier, which does not necessarily skimp on quality since they are also designed to serve their purposes best.

Polypropylene (PP) - a recyclable material that is both plastic and fiber, polypropylene can tolerate heat better than PVC. PP is also resistant against moisture but is susceptible to degradation when constantly exposed to UV.

Polyvinyl Chloride (PVC) - the most commonly used and also the lowest in cost, PVC drift eliminators are resistant from corrosion. However, PVC is also known to have toxic byproducts.

Metal - with its more robust nature, steel drift eliminators are ideal for use in higher temperatures and container shipments. However, metal is prone to corrosion, but can be reinforced with a coating for protection.

Cooling Tower Drift Eliminators The The Specifications

The number of models available in the market today will come with varied specifications that may confuse those who are new in the business. While the intended use will vary, these are the common specifications that you should always look at:

-

Installation type (counterflow or crossflow).

-

Design Type (blade type, cellular type, and cassette type, etc.).

-

Dimensions (depth, width, and length).

-

Blade spacing and thickness (when applicable).

-

Maximum span

-

Sheet size (when applicable)

-

Gauge

The Ideal Features of Drift Eliminators

Finally, when choosing from your narrowed down options, make sure that the model meets most, if not all of the following features:

-

Certified and compliant with safety regulations.

-

Easy to use, inspect, and maintain.

-

Can maintain total drift loss by at least .001%.

-

High performance.

-

Cost efficient.

-

Adjustable and flexible for conversion.

-

Seamless in process

Conclusion

If drift eliminators have been used for many years, drift eliminators should be replaced. We have provided you with all the different drift eliminators you need, such as marley cooling tower drift eliminators, evapco drift eliminator kit. you can consult with cooling tower drift eliminator suppliers with more confidence. With all the benefits that businesses with cooling towers can get from drift eliminators, it is apparent that they are quite a beneficial product.