Understand The Important Role Of Water Eliminators In Cooling Towers

Cooling towers are an important part of industrial processes, helping to remove excess heat in a variety of applications including power plants, manufacturing facilities, and HVAC systems. However, while these towers can effectively cool water, they can also create "drift" that can create environmental and operational challenges. This is where the Sara Drain Eliminator comes into play.

What is drift?

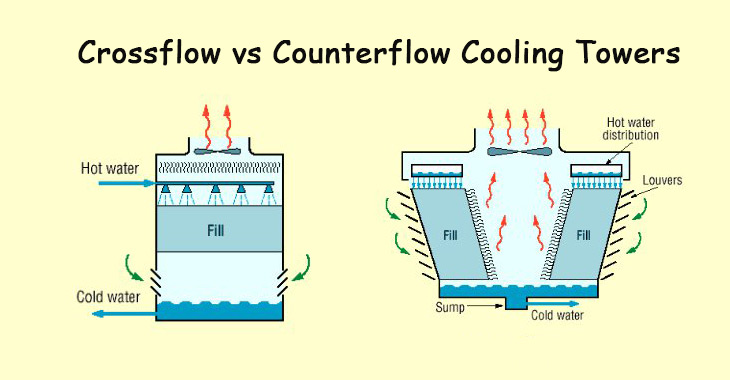

Drift refers to small water droplets carried by the air exiting the cooling tower. These droplets contain trace amounts of chemicals and minerals in the circulating water, making them a potential source of environmental contamination and equipment corrosion. Additionally, drift can lead to increased water consumption and operating costs as valuable water is lost from the system.

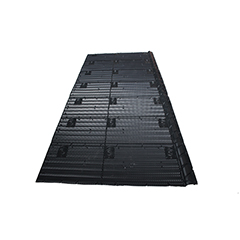

The function of water eliminator

Drift eliminators are specially designed components installed within cooling towers to reduce the dispersion of water droplets into the surrounding atmosphere. These devices utilize a combination of barriers, baffles, and direction changes to capture and redirect drift back into the tower basin, preventing it from escaping into the environment. Our company has high-quality water eliminators for sale, welcome to inquire.

The main uses of water eliminators:

Environmental Protection: By reducing the discharge of water droplets, water eliminators help minimize the environmental impact associated with cooling tower operations. This is especially important in areas with strict water conservation and air quality regulations.

Equipment Preservation: Drift eliminators play a vital role in protecting the integrity and service life of cooling tower components. They reduce the risk of corrosion and deterioration by preventing water droplets from reaching sensitive equipment and structures such as fans, motors and building surfaces.

Water conservation: Drain eliminators help conserve water by capturing drift and redirecting it back into the tower basin. This helps maintain the overall water balance within the cooling system, reducing the need for makeup water and lowering operating costs.

Energy Efficiency: Drift eliminators indirectly support energy efficiency by ensuring cooling towers are operating at optimal performance levels. They help optimize cooling tower efficiency and minimize energy consumption by maintaining proper water distribution and reducing load on downstream equipment.

In cooling tower operations, water eliminators are indispensable allies and are the frontline defenders against environmental contamination, equipment degradation and excessive water use. By understanding their important role and ensuring proper maintenance and replacement, industries can maintain environmental stewardship, maintain equipment integrity and improve cooling system efficiency.

You might also like

Categories

Trending