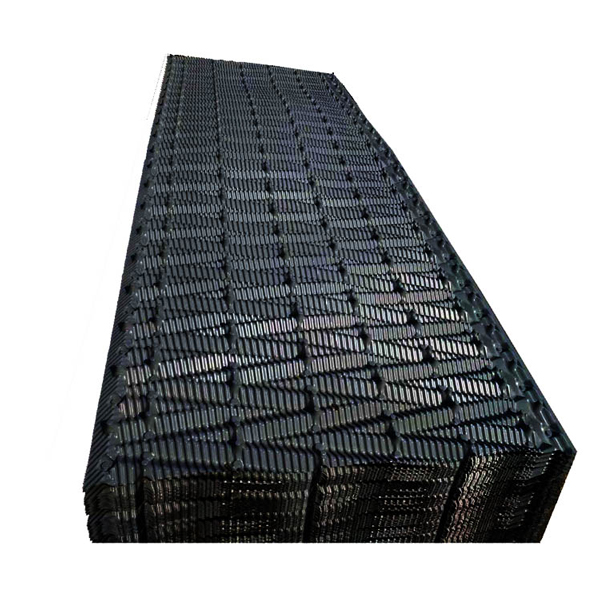

Cooling Tower Fills

A List of Cooling Tower Fills

Cooling Tower Fills Types

What is Cooling Tower Filling

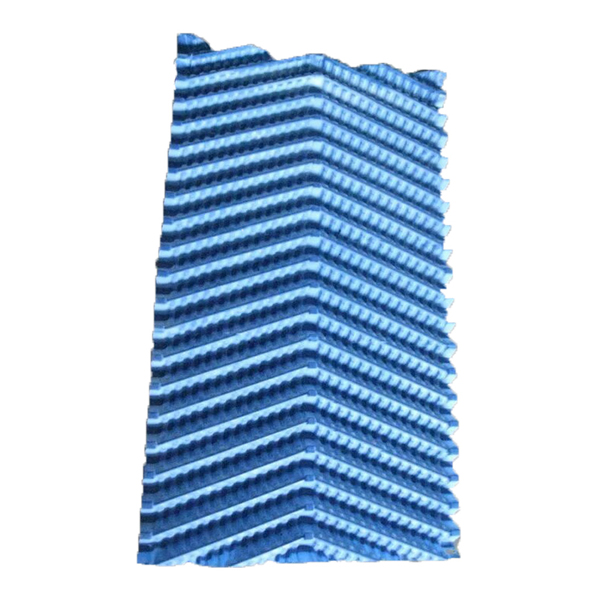

Cooling tower packing is an integral component of cooling towers used in various industrial processes and air conditioning systems to remove excess heat from water. Fill, also known as cooling tower fill media or fill, is structured material placed within a cooling tower to increase the surface area for air and water to interact.

The primary function of cooling ower packing is to facilitate the efficient transfer of heat from the hot water in the tower to the cooler air passing through the tower. The process typicaly involves water pouring over the fill while air is forced or naturally drawn into the tower, causing evaporation and heat exchange.

Cooling tower packing is designed to maximize contact between water and air by providing a large surface area for water to spread thinly and create turbulence. This contact enhances the evaporation process, which is the primary mechanism by which cooling towers dissipate heat.

Benefits of using Cooling Tower Fins

Using cooling tower packing offers several advantages, including:

Improved heat transfer efficiency: Cooling tower packing increases the surface area available for heat exchange between water and air. This improved contact allows for more efficient heat transfer, resulting in better cooling performance.

Reduce energy consumption: By improving heat transfer efficiency, cooling tower packing can help reduce energy consumption of the entire cooling system. This can lead to significant cost savings over time, especially in large-scale industrial applications.

Water Conservation: The efficient heat transfer provided by cooling tower packing allows for greater cooling capacity while reducing water usage. This helps conserve water as less water is required to achieve the desired cooling effect.

Extended equipment life: Cooling tower infill helps maintain optimal operating conditions within the cooling tower, reducing the workload on other components such as pumps and fans. This extends the life of the equipment and reduces the need for maintenance.

Improved performance stability: Properly designed and installed cooling tower packing helps stabilize the water temperature within the tower and reduce fluctuations in cooling performance. This stability ensures consistent cooling output even under varying operating conditions.

Resistant to fouling and corrosion: Some cooling tower fills are designed to resist fouling and corrosion, which can occur due to the buildup of debris, scale, or biological growth. This helps maintain the efficiency and longevity of your coolingtower system.

Flexibility and Versatility: Cooling tower fill is available in a variety of configurations and materials to accommodate different cooling tower designs and operating conditions. This flexibility allows for customization based on specific project requirements and performance goals.

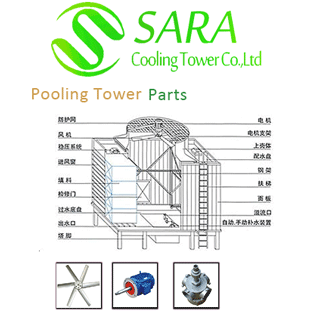

Types of Cooling Tower infill

There are many types of cooling tower packing, each designed to suit specific cooling tower applications and operating conditions. The following are the most common types:

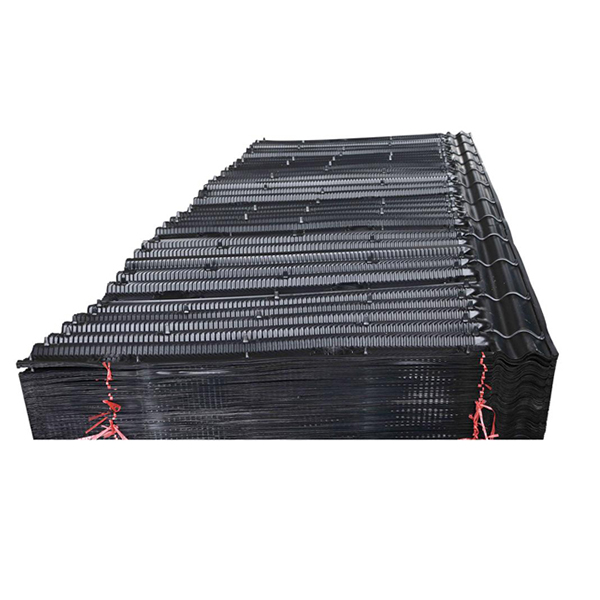

Splash Fill: Also known as splash bar fill or splash grid fill, splash fill consists of a horizontal deck or tray with protrusions or louvers. As water flows through these trays, it breaks up into smaller droplets, increasing the surface area exposed to airflow. Splash fill promotes turbulence and mixing between water and air, promoting efficient heat transfer through evaporation. They are commonly used in counterflow cooling towers.

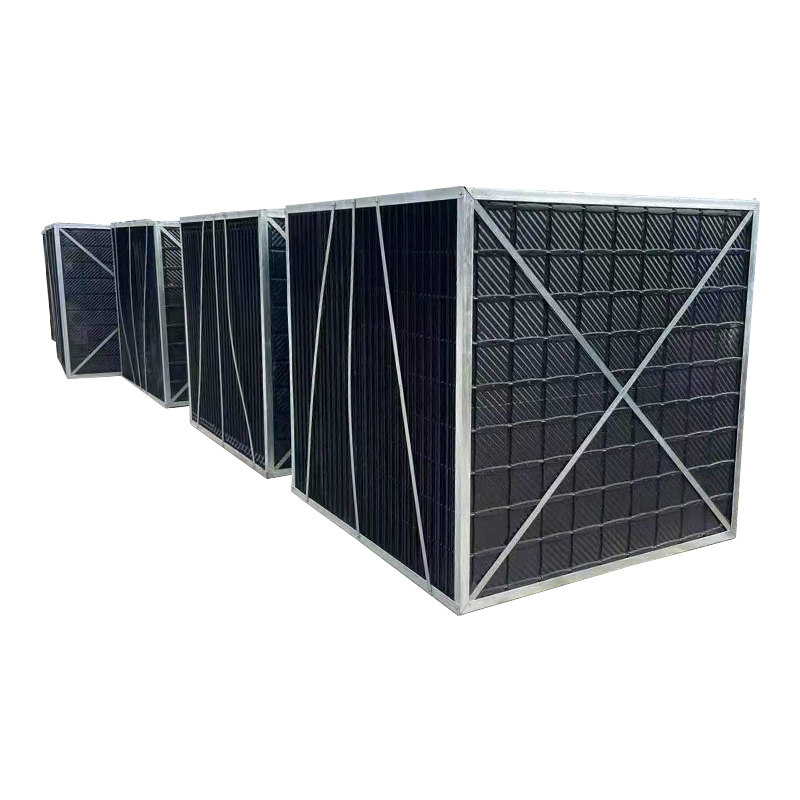

Counterflow Fill: Counterflow filling is specifically designed for use in counterflow cooling towers, where air flows vertically upward and water flows downward. These fills are typically vertically oriented and optimized to provide efficient heat transfer in counterflow applications. Counterflow filling can include splash, film, or hybrid designs, depending on the desired performance goals and operating parameters.

Cross-flow fill: Cross-flow fill is tailor-made for cross-flow cooling towers, where air flows horizontally over the falling water. These fills are typically oriented horizontally and are optimized to provide efficient heat transfer in cross-flow applications. Cross-flow filling can also include splash, film, or hybrid designs, depending on the specific requirements of the cooling tower.

Advantages of using cooling tower fills

Using cooling tower packing has several advantages in industrial and commercial cooling applications:

Improved heat transfer efficiency: Cooling tower packing increases the surface area for water and air to interact, promoting efficient heat transfer through evaporation. This improves cooling performance and reduces energy consumption compared to unfilled systems.

Increased cooling capacity: By maximizing thecontact area between water and air, cooling tower fill allows for greater heat removal capacity per unit of water circulated through the tower. This increases the overall cooling capacity of the system, allowing it to handle higher heat loads efficiently.

Water Conservation: The efficient heat transfer provided by cooling tower packing allows for effective cooling while reducing water usage. This helps conserve water and helps reduce water consumption and wastewater production, benefiting the environment and operating costs.

Energy Savings: By improving heat transfer efficiency, cooling tower infill can help reduce the energy consumption associated with cooling tower operation. By optimizing the cooling process, less energy is required to maintain the required temperature levels, resulting in cost savings and environmental benefits.

Extended equipment life: Cooling tower infill helps maintain optimal operating conditions within the cooling tower, reducing the workload on other system components such as pumps, fans and heat exchangers. This extends the life of the equipment and reduces maintenance requirements, saving time and money in the long run.

Improved process stability: Cooling tower packing provides stable and efficient cooling, ensuring consistent temperature control in industrial processes and HVAC systems. This helps maintain product quality, equipment reliability and overall process stability, minimizing the risk of costly downtime or production interruptions.

Versatility and adaptability: Cooling tower fill is available in a variety of configurations and materials to accommodate different cooling tower designs, operating conditions and performance requirements. This flexibility allows for customization and optimization based on specific application needs, ensuring optimal cooling performance in different industrial and commercial environments.

Commonly used materials for cooling tower fill

Cooling tower fill is typically made from durable materials that resist corrosion, biological growth, and chemical degradation. Some common materials used in cooling tower fill include:

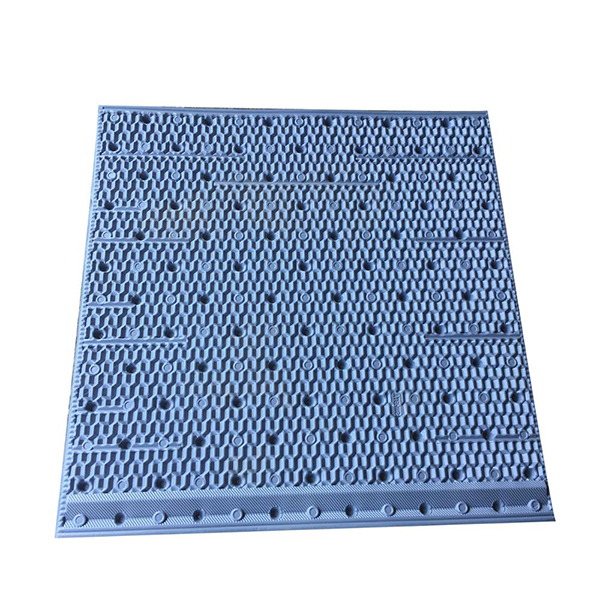

Polyvinyl Chloride (PVC): PVC has excellent resistance to corrosion, UV degradation, and biofouling and is one of the most widely used materials for cooling tower fill. PVC fill is lightweight, cost-effective, and easy to install, making it suitable for a variety of cooling tower applications.

Polypropylene (PP): Polypropylene is another popular choice for cooling tower fill, known for its high chemical resistance, mechanical strength, and thermal stability. PP fillers offer excellent resistance to corrosion, abrasion and biological growth, making them suitable for harsh operating conditions.

High Density Polyethylene (HDPE): HDPE is a durable thermoplastic known for its excellent chemical resistance, impact strength, and UV stability. HDPE fill is resistant to corrosion, dirt, and environmental degradation, making it suitable for outdoor cooling tower installations.

Polyethylene (PE): Polyethylene fillers offer good resistance to corrosion, UV degradation, and biological growth. PE packing is lightweight, cost-effective and easy to handle, making it suitable for use in cooling towers with mild operating conditions.

PVC/PP Composite Filling: Composite filling combines the benefits of PVC and PP materials with enhanced chemical resistance, mechanical strength and durability. Composite fill is often used in cooling towers where a combination of properties is required to meet specific performance requirements.